The GARANT Master Steel range – experts for milling steel

GARANT Master Steel milling cutters deliver maximum precision, top quality and impressive tool life

Optimised geometry, state-of-the-art manufacturing methods and high-quality components – GARANT has created a new machining generation. Thanks to its extremely large flutes, the geometry allows excellent chip evacuation at higher feed rates. This produces outstanding results in high-strength steels (tensile strength approx. 1000 N/mm² or higher).

GARANT Master Steel milling cutters impress thanks to their particularly good performance in steel processing. They can also be used to process stainless steel. The extensive GARANT Master Steel product range has the optimal solution for any machining task – finishing, roughing, plunging (drilling) or ramping.

The special properties of Master Steel:

- Maximum smoothness of cutting action and performance thanks to unequal spacing

- Very long tool life

- Optimal chip evacuation thanks to large flutes

- For general-purpose use: Green ring (steel / stainless steel / cast iron)

The GARANT Master Steel milling cutters:

Discover all the GARANT Master Steel milling cutters

GARANT Master Steel PickPocket

GARANT Master Steel HPC milling cutter

GARANT Master Steel HPC solid carbide finishing cutter

GARANT Master Steel SlotMachine

GARANT Master Steel PickPocket

This GARANT Master Steel universal milling cutter represents a new dimension in mono machining: It combines power and versatility, offering up to 80% better performance and a longer tool life. It displays outstanding performance in milling, ramping and even drilling.

1. Innovative geometry

Optimum chip breaking when ramping

2. Unequal helical pitch

For smooth running

3. Green ring for universal use

Main application field: steel

4. Special core diameter increase

Ensures optimum stability during the machining process

5. Recessed drill tip

Extremely large recess

For aggressive ramping and plunging

6. Crescent-shaped cutting edge

End face, under the centre

Unequal spacing

Optimised for HPC milling

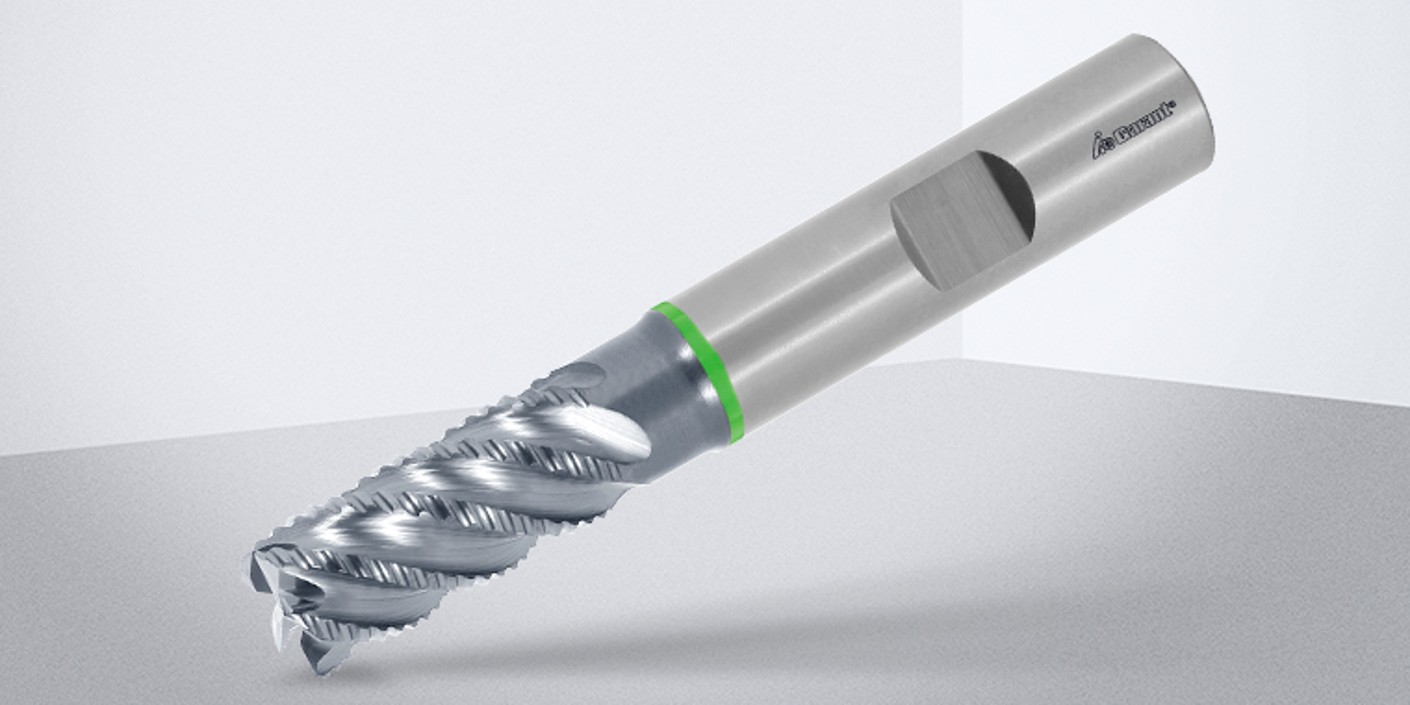

GARANT Master Steel HPC milling cutter

Unique quality, impressive durability and highest precision characterise the new GARANT Master Steel HPC roughing end mill. With optimised geometry, state-of-the-art manufacturing methods and high-quality components, GARANT has created a new machining generation. Thanks to its extremely large flutes, the geometry allows excellent chip evacuation at higher feed rates. It was specially developed to enable outstanding tool life and smooth cutting action, even when processing challenging materials. The tool’s performance is supported by unequal spacing, dynamic spiral angles and perfect grinding quality. The unique grinding quality is also reflected in the honed cutting edges. As a result, the milling cutter has a very homogeneous cutting edge, leading to increased tool life whilst keeping wear to a minimum and still achieving good surface quality. A selected high-performance substrate combined with a newly developed coating also guarantees outstanding tool life.

All characteristics of the GARANT HPC roughing end mill at a glance:

- Dynamic spiral angles for smooth cutting action

- Honed cutting edge for low wear and good surface quality

- Large flutes for higher feed rates

- Unequal spacing for low-vibration running

- High-performance substrate with special coating for outstanding tool life

GARANT Master Steel HPC solid carbide finishing cutter

For general-purpose use in high-performance milling - the GARANT Master Steel HPC.

- Increased productivity due to significantly higher overall feed rates

- Very high surface quality in very short cycle times

- All diameters from size 6 can be reground

- Very high infeeds due to cutting lengths up to 5×D

1. Unequal spacing of cutting edges: Reduced vibration; increased smoothness of cutting action

2. Optimised flute profiles: Optimum chip evacuation via seven cutting edges

3. Precision-ground cutting edges: Ideal sharpness when coated

4. Green ring: For general-purpose use (steel / stainless steel / cast materials)

5. Balanced tool geometry: DIN ISO 1940 – G2.5

6. Optimised substrate due to adapted Co content: Improved bending strength and toughness

7. Minimised wear: At the peripheral cutting edges due to specifically rounded-off cutting edges.

8. Very stable core diameter: Ensures extreme robustness and tool stiffness; avoids tool deflection

9. Cutting edge with 45° chamfer: For edge protection

Find the right GARANT Master Steel SlotMachine solid carbide roughing end mill:

Solid carbide finishing cutter HPC in action

In a very short time the solid carbide finishing cutter HPC delivers very high surface quality, increasing your productivity due to its significantly higher feed rates. Thanks to its unequal spacing, the GARANT Master Steel finishing cutter reduces vibration and noticeably increases the smoothness of the cutting action. See for yourself in our video.

GARANT Master Steel SlotMachine

Overcomes performance limits in high-performance rough grinding

The new five-edge end mill achieves 25% higher process efficiency than a classic four-edge end mill. The innovative knurled profile minimises the cutting pressure, putting less load on the component. As a result, the new GARANT Master Steel SlotMachine high-performance roughing end mill is particularly suitable for milling deep slots from solid.

The advantages of the new high-performance milling cutter at a glance:

- TOP smooth cutting action thanks to unequal spacing

- TOP efficiency thanks to five cutting edges

- TOP chip evacuation thanks to extremely small swarf

- TOP stability thanks to reinforced core diameter

- TOP chip formation thanks to innovative knurled profile

Non-stop roughing – performance without limits

Our five-edge Master Steel SlotMachine HPC for high feed rates – even in slots milled from solid up to 2×D

- Green ring - For general-purpose use, mainly for steel and cast materials

- Extremely stable tool core - Reduces the risk of fracture

- Optimum chip evacuation - Thanks to directional chip evacuation

- Unequal spacing on tool - Ensures smooth cutting action and reduces vibration

- Precisely honed cutting edges – minimises the risk of break-outs

- Generous centre freedom - Enables plunge angles of up to 10°

- Innovative coating - For optimum wear behaviour; reduces heat input

- Innovative knurled profile - Creates more space for additional cutting edges and allows for smaller flutes

- Ultra-fine grain structure - Extreme flexural strength and wear resistance

GARANT Master Steel SlotMachine in action

The tool geometry of the solid carbide roughing end mill with the innovative knurled profile for HPC creates very fine, tightly rolled and optimally evacuated swarf. Tightly rolled swarf allows for smaller flutes which create more space for additional cutting edges. As a result, it is possible to achieve a denser chip volume and constant swarf removal. The new solid carbide milling cutter GARANT Master Steel SlotMachine adds to the GARANT Master Steel product range for full-slot milling in steel with high feed rates.